Manufacturing Process of U Tubes

Your search ends here, as you’re at the right place to discover more about U Tubes Manufacturing Process. Krystal Global Engineering Limited manufacturing unit is one of the leading manufacturers, suppliers, and exporters of U Tubes, available in various sizes and lengths. Manufactured using qualitative raw material and modern technology, these tubes are also tested on various quality parameters before being delivered to our clients all across the globe. Apart from manufacturing these tubes, we also provide customization and design modification services, if required by the customers.

Material Composition

The product is made of high-quality materials, which are all non-toxic and safe to use. The length and thickness of tubing can be customized, according to the client’s demand. A variety of dyes are available for selection. Most tubes are semi-finished products that require minimal processing before being sold as finished goods. Also, most tubes have a standard outside diameter, wall thickness, inside diameter, etc., so customers don’t need to worry about these parameters during production.

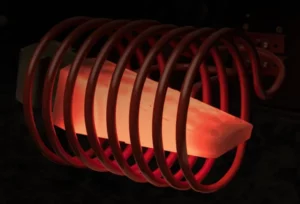

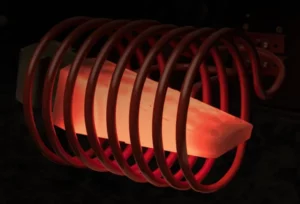

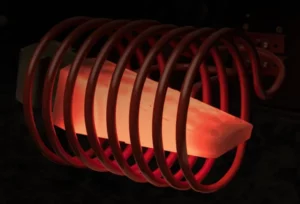

Processing Procedure

The U tube manufacturing process begins with cutting a circular strip of metal. The size and shape of these tubes vary according to requirements, and then they are welded together in series. The centre hole is made after welding and openings at both ends. These openings help in fastening nuts at one end, while allowing unidirectional water to flow through them. After these steps are completed, U tubes can be produced as per requirements by machining or casting them.

Quality Control Procedure

There are three important stages in the U tubes manufacturing process. The first is that we buy raw materials from different suppliers and check them before processing U tubes. These materials are quality verified by our expert team on different parameters to provide the best products to our clients at a reasonable price. The materials supplied to us should be free from defects and provide a smooth finish for welding purposes. The material which does not meet these standards is rejected before further processing.

Finishing

The finishing process is one where we carefully inspect our products. Since each batch of materials is a little different, we want to ensure that our tolerances are correct and that no defects or debris make it through to our customers. After a lot of tests and time spent refining these processes, we have determined what works best for us and have set up state-of-the-art machines to automatically do much of our finishing work.

Inspection

The first step in the manufacturing process is inspection. In order to make sure that you get only top quality products from us, we subject all our raw materials to proper and timely inspections. The first inspection is done when we accept our material from our vendors. We make sure that there are no defectives and if any, then we take them back for replacement and get replacements. Our experts keep a check on colours and finishing of raw materials so that you do not face any problems later in the assembly process or after-sale services.

Packaging And Delivery

We package every order carefully before sending them to customers all over India. We use state-of-the-art packaging material to ensure that your order is delivered safely to you. When an order is placed on our website, we send it directly to our suppliers, where they begin production immediately. The products are inspected after manufacturing and then sent for packaging before being shipped out to us. Packaging is done in air-conditioned rooms with quality inspection software at each step along with visual inspections.

Krystal Global Engineering Limited

Since 2006, Krystal Global Engineering Limited (KGEL) is committed to supplying high-quality products and services at competitive prices and serving their customers with innovative ideas. KGEL is one of the leading manufacturers & exporters of coil formed tubes worldwide. Incepted in the year 1990 by a visionary group, KGEL has emerged as a reputable Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

Manufacturer and Supplier of U Tubes

At Krystal Global Engineering Limited, we are a leading manufacturer and supplier of a high-quality range of U Tubes. We use advanced tools and equipment to manufacture these tubes in compliance with international quality standards. Apart from superior quality, our tubes are highly reliable and known for their corrosion resistance. We can offer these tubes in different sizes as per clients’ specifications. Further, we can provide them at market leading prices to our esteemed clients. So, place your orders now!

Our Range

- Specifications : ASME / ASTM A 213 / A 688 & TEMA RCB – 2.3.1 / DIN 28179

- OD : 9.53 mm to 50.80 mm

- Thickness : 0.5 mm to 3.68 mm

- Leg Length : Up to 14 Meters Leg Length (Depending Upon Size)

- Process Features : Bright Annealed, Solution Annealed – Picked – Passivated

- IN-SITU MetallographyU-Bends 1.25D Up to 1000 mmFull Length Stress Relieving (SR) & DP after U-Bending

- Surface Finish : Bright Annealed (CFA), Solution Annealed (CFD), Polished (APP)